This Information page presents a summary of the key processes involved in the treatment and supply of drinking water.

What is Water Treatment?

The raw (untreated) waters that are the sources of our drinking water supplies usually are treated by a series of processes to make them safe for human consumption.

The objective is to produce water that is chemically safe, free of harmful microbes, pleasant to drink with respect to odour, taste and appearance and non-corrosive towards pipes and fittings. The quality of drinking water and water used for food production is subject to the provisions of the EC Drinking Water Directive 1998.

http://ec.europa.eu/environment/water/water-drink/legislation_en.html

(https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX:31998L0083)

These standards define values for chemical, microbial and physical parameters for water at the point of delivery to the consumer (normally taken as the kitchen tap). They are implemented in the UK through a series of regulations. These can be found on the Drinking Water Inspectorate website:

(http://dwi.defra.gov.uk/stakeholders/legislation/index.htm)

http://dwi.defra.gov.uk/consumers/advice-leaflets/standards.pdf)

The degree of treatment depends on the source of the water (river, reservoir or underground aquifer) and the nature of the river basin. The implementation of the Water Framework Directive will, through the river basin management process, set in place procedures for safeguarding the sources of water from such contaminants as pesticides and harmful micro-organisms which may be present in raw waters. For example, pesticides and harmful micro-organisms may be present in rivers draining agricultural catchments. Groundwaters, derived from aquifers where the strata are natural filters, may contain relatively few pollutants. Industrial effluents may render water very difficult to treat. It is logical to invest and legislate for the protection of water bodies against pollution rather than apply complex treatment to our water sources after pollution has occurred. The Water Framework Directive is important for achieving such protection.

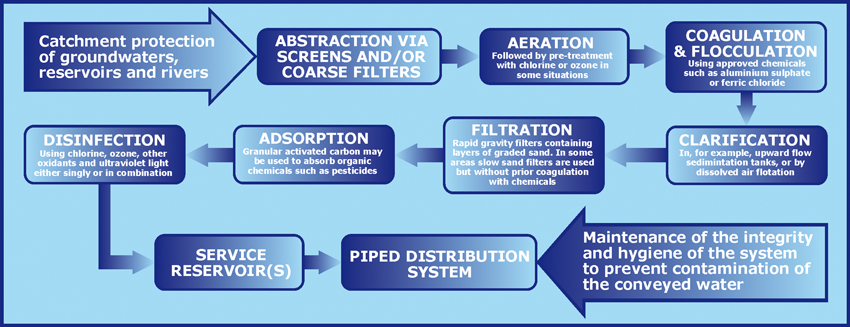

The concept of multiple barriers for water treatment and supply is the basis of safe drinking water production. These barriers are the protective measures applied to sources of raw water and piped distribution systems and the process stages in the treatment plant. The following process stages (barriers) have been applied in various combinations to treat waters in the UK.

Screening and Micro-strainers

Debris such as leaves and plant fragments are removed by passing the water through a series of coarse meshes. Micro-strainers remove fine solids by passage through a fine steel or plastic mesh.

Aeration

Aeration, using a cascade or fountain, helps remove dissolved iron, manganese and volatile organic compounds.

Chemical Coagulation

Colloidal particles, including many micro-organisms, can be induced to agglomerate into larger particles and flocs by the addition of certain metal salts such as aluminium sulphate or ferric chloride, which precipitate as hydroxide flocs. These flocs can then be removed with the entrained and adsorbed pollutants.

Clarification

The coagulated particles and flocs can be removed by sedimentation in a variety of units such as horizontal flow sedimentation tanks or upward flow floc blanket clarifiers. An alternative method, called dissolved air flotation, uses small air bubbles to float floc particles to the surface of the tank where they are removed by a scraper mechanism.

Filtration

This is a widely used water treatment process. Water is passed through porous beds of graded sand or another inert material. There are two common types, rapid or slow, depending on construction and grade of filter media. Rapid filters are normally used after chemical coagulation and clarification stages and can either operate under gravity or pressure flow. To keep the filters clean, they are periodically washed and the wastewater itself is treated before recycling or discharge. Slow sand filters depend on microbial activity as well as the filtration process for their efficacy and operate under gravity flow. A biologically active surface layer builds up which is a vital part of the filter’s operation. The surface layer has to be scraped off at intervals to remove algae and restore filtration rates and once cleaned time is needed to allow the surface layer to re-establish before optimum performance is achieved.

Activated Carbon Adsorption

Activated carbon is produced by a controlled combustion of carbonaceous material such as wood or coconut shells. This produces a black porous material with a very large surface area per unit volume and a high affinity for organic compounds. Many treatment works, especially those treating lowland river-derived waters, employ granular activated carbon in adsorption vessels for the removal of trace organics (e.g. pesticides), taste and odour compounds and algal toxins.

Disinfection

The most important objective of water treatment is the removal or inactivation of pathogenic organisms, which include a wide range of bacteria, viruses and protozoan parasites. Strong oxidising chemicals are used, normally as a final process stage, but also at intermediate stages within many works. Chlorine and ozone (a chemically active form of oxygen) are the most common chemical agents. Ultra-violet light is also employed as a non-chemical means, in some situations. However, before being pumped into storage and the pipe network most works add chlorine to maintain a residual disinfectant in the water supply to prevent it becoming infected between the treatment works and the customer’s tap.

Treatment Process Flowchart

The diagram below summarises a typical sequence of unit processes used to treat a lowland river supply. Many variations occur in practice, and it is not unusual for pristine groundwaters to be treated by disinfection alone. However, as stated earlier, the complexity of the treatment processes is dependent on the pollutant risks that are identified in the catchments for each source of drinking water. The integrated approach used in the application of the Water Framework Directive will greatly assist the identification and monitoring of such risks.

You are here:

Tel: +44 (0) 1628 891 589 Fax: +44 (0) 1628 472711

Registered Office: Allen House, The Listons , Liston Road, Marlow,

Buckinghamshire SL7 1FD, UK © 2015 FWR All rights reserved.

The Foundation for Water Research is a company limited by guarantee,

registered in England, No 525927 and a registered charity No 1086685.